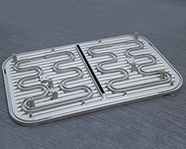

For over 30 years, LYHD has been dedicated to providing companies with superior die casting molds and pressure die casts. We also can provide the processing service of metal parts and subsequent finishing services, such as spraying, electroplating, polishing, shot blasting, and sanding, etc. Equipped with many high-precision equipment such as CNC machining centers, lathes, milling machines, EDM, etc., LYHD can reach an annual output of 300 sets of dies. We can perform pressure die casting in a wide range of applications including medical devices, vehicles, outdoor lightings, and food machinery, etc.

Design

Positioned as the industry leader with more than 30 years of experience in making die casting molds for countless industries, LYHD can provide the most suitable solutions for die casting molds and metal processing upon your request. We have a team of highly experienced mold design engineers, one of whom has been engaged in mold design and manufacturing for more than 40 years. With our extensive experience and professional knowledge, we can address any question or concern that our customers may have, please feel free to contact us. Before making the die, our technical team will discuss your requirements with you in detail to produce the most suitable die casting mold. Our experienced engineers can also predict the wear position of the mold and come up with solutions to save you time in maintaining the mold, thus bringing you higher profits.